This is the second part of electric car operation. Is explained other components and it’s functions.

To see the first part, click in the button below.

Electric car (Part 1)Click here

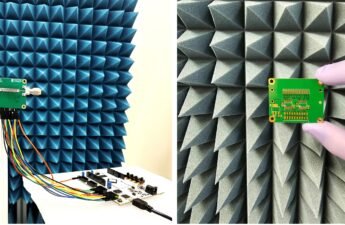

Converters

Electric cars use DC/DC down or buck converters, get the battery’s DC voltage and decreases the level to supply other electronic systems like sensors and instruments. In addition to recharge auxiliaries batteries.

Some electric cars have converters to provide input voltage to inverters. The operation of converters will be subject to another post.

Regenerative braking

In the induction motor, the rotor’s speed is lower than magnetic field’s speed or synchronous speed n_{s}. However, if the rotor spins faster than n_{s}, it becomes a generator.

When the driver releases the foot from accelerator, the inverter sends a negative torque signal to motor, changing the field rotation direction. The magnetic field’s speed is reduced and stays lower than the rotor. The induced current which circulates in rotor produces a magnetic field. Energy generated in the motor is used to recharge the battery pack. Hybrid cars like Toyota Prius also use regenerative braking.

In the internal combustion cars, kinetic energy from break is wasted in form of heat. Due to attrition of wheel and brake disks. The electric car still uses brake disks to vehicle stops completely. In the figure below, the arrow’s orange part is when the brake is applied, comparing the regular car with combustion with the electric Model S.

Transmission

The electric car does not have gear transmission, because the induction motor is efficient is many conditions. The gear box between electric motor and wheels axis is to increase the torque and decrease the rotation speed.

To move in reverse, just change the order of phases to motor.

Cooling system

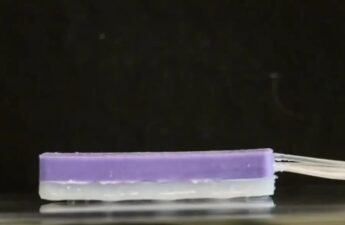

How to dissipate the heat of batteries and other components? A coolant, mix of water and ethylene-glycol, is used to absorb heat. The ethylene-glycol (C_{2}H_{6}O_{2}) is transparent and also has anti-freezing properties, because batteries degrade with very low temperatures. This is the ethylene-glycol`s molecule.

The moisture passes by batteries modules, absorbs heat and goes to a heat exchanger, where it is dissipated to outside the vehicle. Each car has it own cooling architecture.

Others Itaipu Binacional`s electric vehicles

The Electric Vehicle program of Itaipu Binacional not only build cars, also manufactures cargo and passenger vehicles. This is the Latin America’s first electric truck, built in partnership with Iveco. Called Daily Elétrico, launched in 2009 and has 100 km of autonomy.

The Electric Agrale Marruá is a vehicle with 4×4 traction, developed in partnership with the companies Agrale and Stola do Brasil. Has 100 km of autonomy and rechargeable sodium batteries.