Stirling engine is of external combustion. Created in 1816 by Stirling brothers to be an alternative to steam engines, which were dangerous at that time.

Operation principle

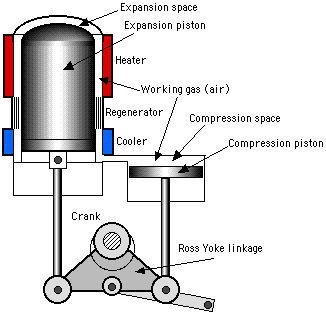

A Stirling engine needs an external heat source. It has two chambers with different internal temperatures, inside these chambers, there is a gas, which expands and contracts, moving pistons. These move a crankshaft, or another mechanism, which turns a flywheel. This motor doesn’t generate gas emissions, therefore it’s a closed cycle.

Stirling cycle

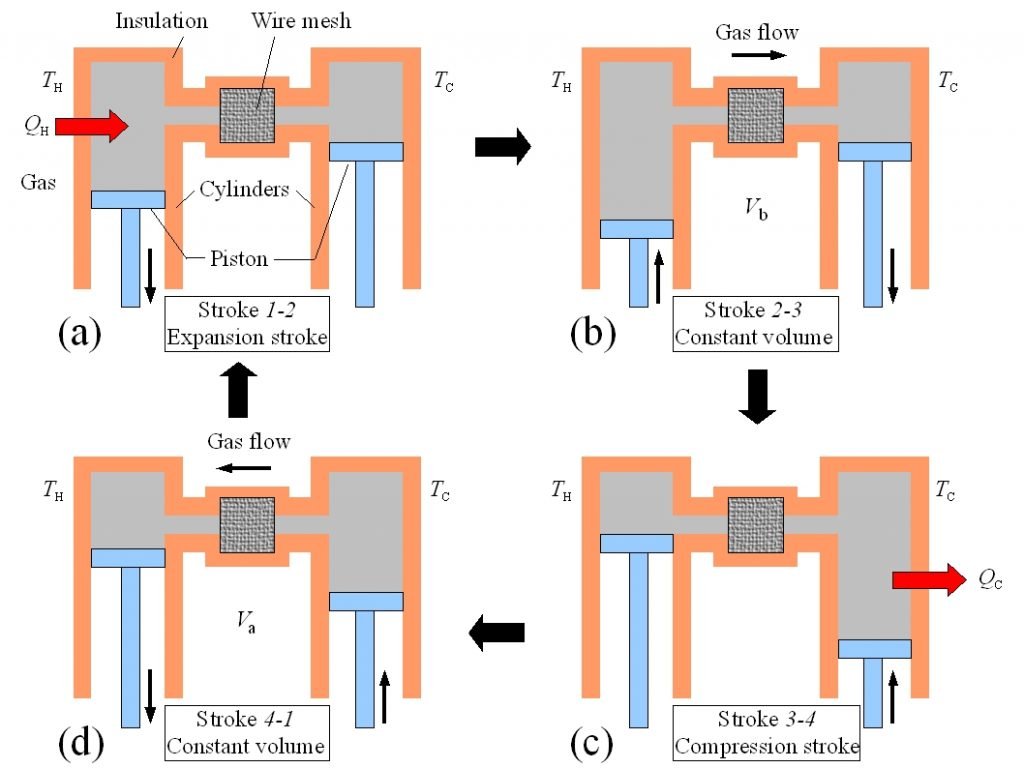

This type of thermal machine follows the Stirling cycle, whose phases are:

- 4 to 1: Isochoric heating (constant volume). An external heat source heats up the chamber, increasing the gas’s pressure.

- 1 to 2: Isothermal expansion. In the hotter chamber, the gas expands, moving the piston.

- 2 to 3: Isochoric or isovolumetric cooling. The gas in hot piston goes to cooler piston due to their motion. They keep moving thanks to mechanical energy stored in the flywheel. The gas passes through a channel that links the chambers and it’s pressure drops due to temperature’s fall.

- 3 to 4: Isothermal compression. The motion of cold piston compresses the gas which goes to the hot chamber.

The Stirling cycle is reversible. By that, it can convert mechanical energy in temperature difference. But in practice, it is much more difficult.

Other details

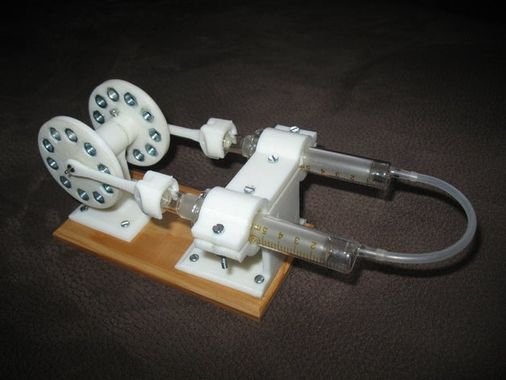

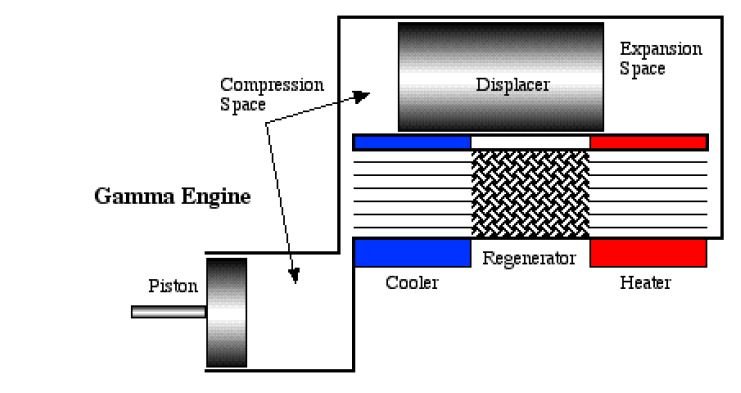

Some motors have a regenerator in the transfer tube for temporary heat storage, helping to keep temperature difference between chambers. The most used gases to make the work are air, hydrogen, or helium. The two latter are for high power application because have higher thermal conductivity and less viscosity. Therefore, transport heat faster and have less loss by friction.

Types of Stirling engines

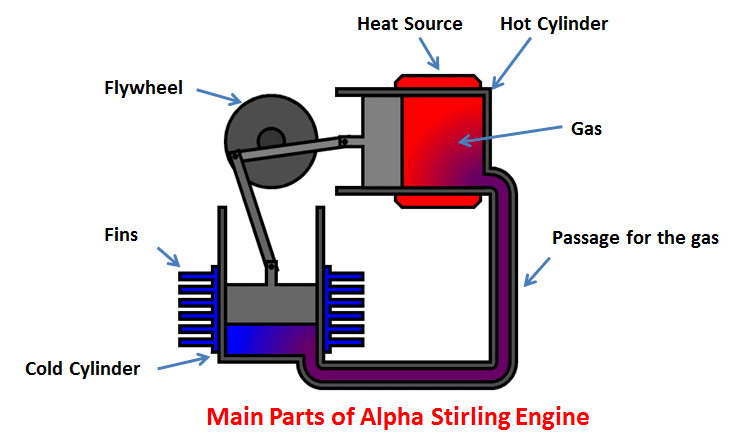

Alpha

In this configuration, the cylinders are separated from each other and linked by a tube with a regenerator. The cylinders can be separated at 90° away.

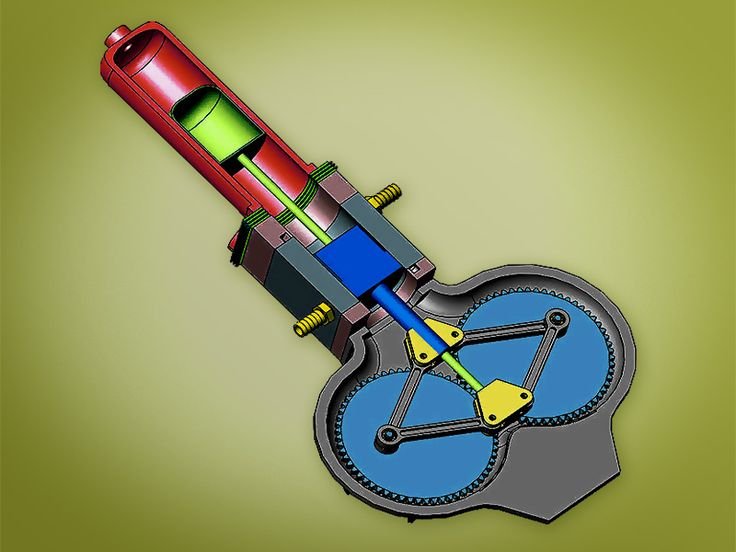

Exists a type of alpha engine called Ross Yoke, it’s one of the most efficient because this mechanism eliminates lateral forces over the piston. Reducing friction a lot.

Beta

In this configuration, exist only a chamber and two pistons. The displacer piston is between hot and cold volumes, while the working piston helps in fluid containment and moves the engine. The beta engine can have a rhombic drive to improve efficiency and balance.

Gamma

The cylinders are separated and the gas displacer is between hot and cold sides of the chamber.

Where is the Stirling engine used?

Stirling engine is quiet, has good efficiency, and can work with any external heat source. It can generate energy from sunlight.

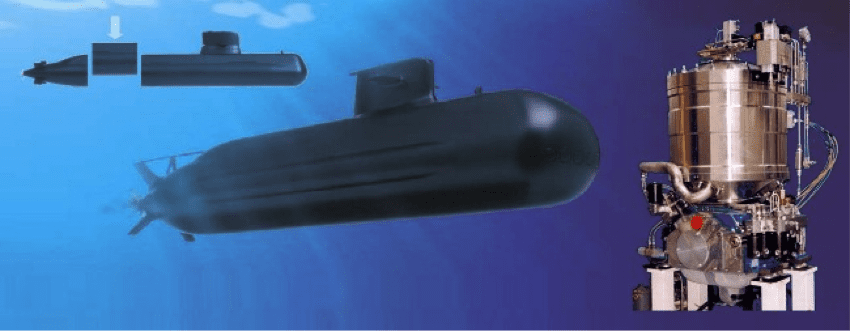

It’s also used in cooling systems and submarines.

This engine isn’t used more often due to the following disadvantages.

- Difficulty to control speed and rotation direction.

- Difficulty in confining the pressurized gas.

- Elevate cost.

The Stirling engine in the thumbnail is Dubrovnik 2, found in Technical Museum Nikola Tesla.

https://www.electricalelibrary.com/en/2020/03/12/technical-museum-nikola-tesla-part-4/