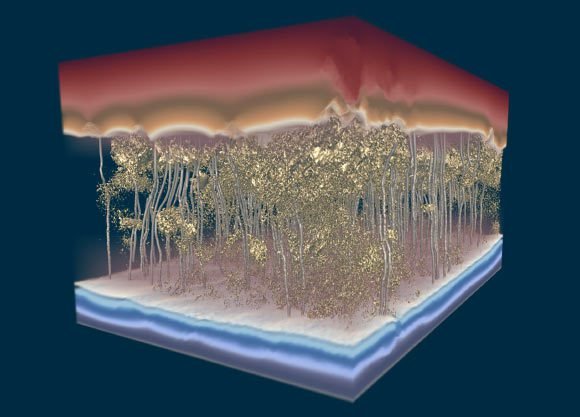

High-efficiency polyamide membranes can be used in water desalinization, thanks to the homogenous internal structure.

Source: Sci News

Dr. Enrique Gomez, Dr. Manish Kumar and their colleagues from Iowa State University, Penn State University, the University of Texas at Austin, DuPont Water Solutions, and Dow Chemical Co. found that creating a uniform membrane density down to the nanoscale of billionths of a meter is crucial for maximizing the performance of reverse-osmosis, water-filtration membranes.

Using transmission electron microscope measurements of four different polymer membranes used for water desalination, they predicted water flow through 3D models of the membranes, allowing detailed comparative analysis of why some membranes performed better than others.

“The simulations were able to tease out that membranes that are more uniform — that have no ‘hot spots’ — have uniform flow and better performance. The secret ingredient is less inhomogeneity,” said Professor Baskar Ganapathysubramanian, a researcher at Iowa State University.

“The simulations themselves posed computtional challenges, as the diffusivity within an inhomogeneous membrane can differ by six orders of magnitude,” said Biswajit Khara, a doctoral student at Iowa State University.

The key to better desalination membranes is figuring out how to measure and control at very small scales the densities of manufactured membranes.

Manufacturing engineers and materials scientists need to make the density uniform throughout the membrane, thus promoting water flow without sacrificing salt removal.

“These simulations provided a lot of information for figuring out the key to making desalination membranes much more effective,” Professor Ganapathysubramanian said.

The team’s work appears in the journal Science.