This is a tutorial about how to make a printed circuit board with the simplest tools in an easy way. I won’t show software here.

Tools needed

- Iron perchloride:

- Piercer board:

- Specific pen to draw in circuit boards (you just need one, I put two for illustration only):

- Tin

- Soldering iron:

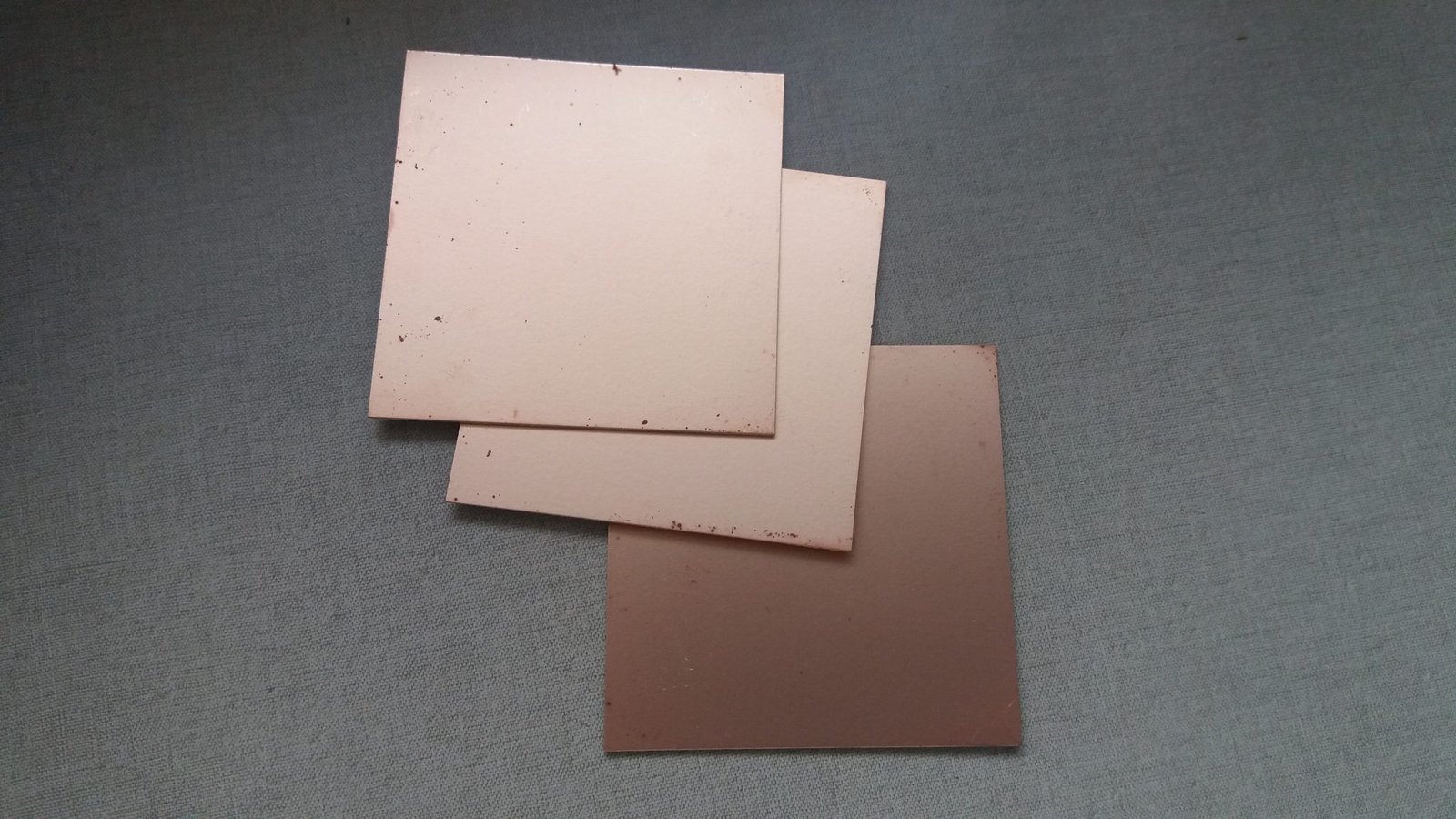

- Phenolite board:

- Board cutter:

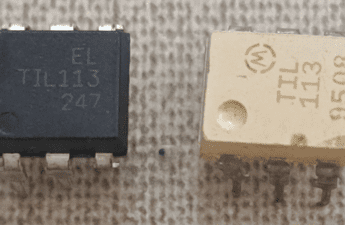

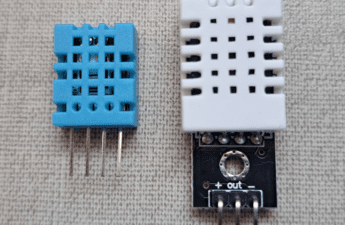

- Components at your choice:

Step by step

Let’s get an astable 555 as an example, the first thing to do is make the schematics.

Then, cut the phenolite board to a desirable size, to do this, hold the board like in the figure.

Then scratch with the board cutter and turn upside down and do the same again.

After enough scratch, force it to take out the desirable part.

Components will stay on the opposite side of the trails, so draw the trails properly considering this. You should draw the remaining areas and connect it with the ground, to make it more resistant to EM interference and to erode faster in the iron perchloride, but you must make a space between the ground and non-ground trail.

Put the iron perchloride in a plastic recipient.

Put the board with the trails face in the iron perchloride and wait for a while.

After the corrosion is complete, make holes in the board according to the schematics.

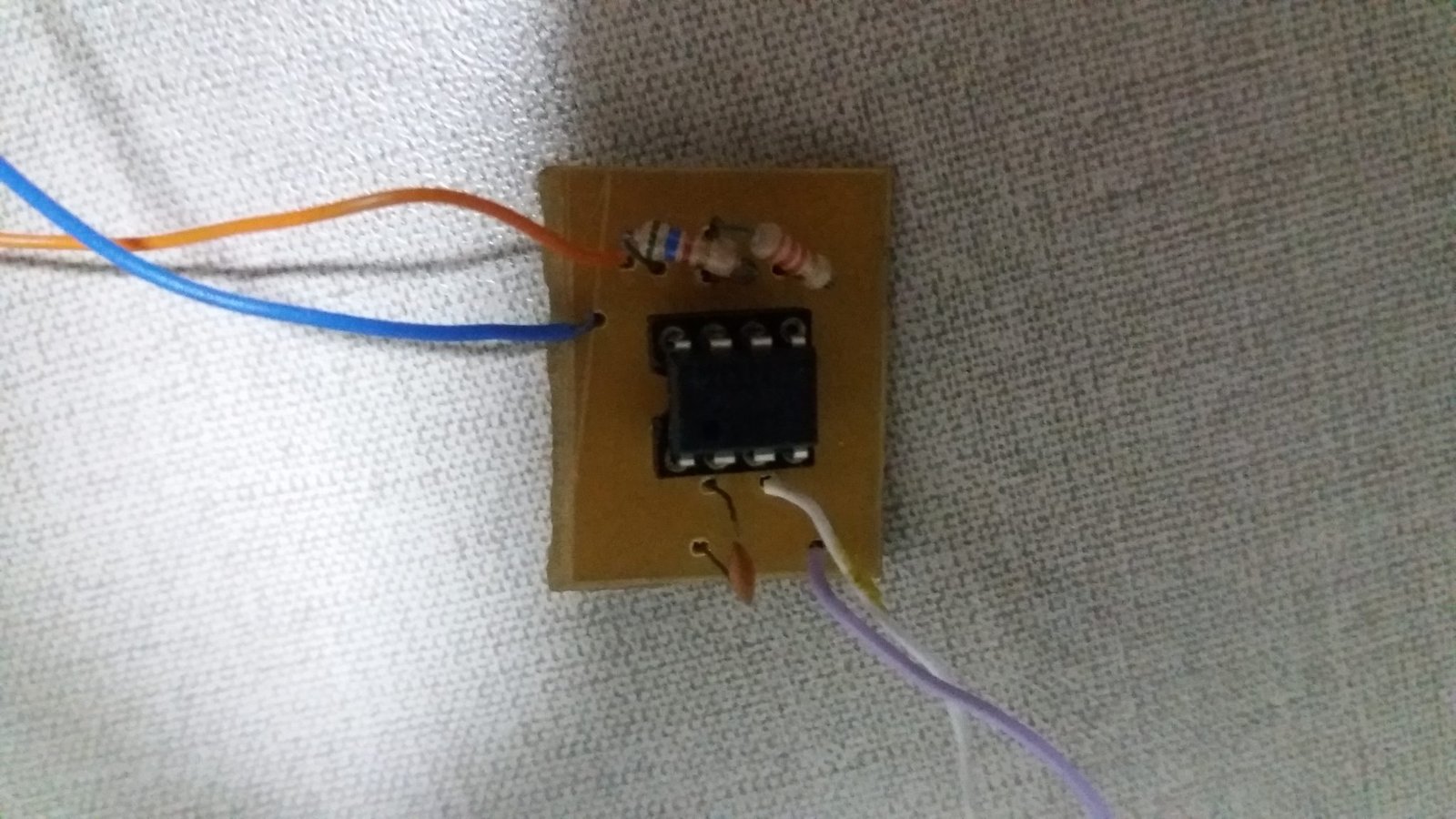

You printed circuit board should be like this:

With soldering iron and tin, sold the components.

The circuit is ready. Now is the test, if you have an oscilloscope, you will be able to see a square waveform in the output.