Optical fibers are a very fast way to send information via light, it can transmit at speed until 100Mps (Megabits per second), has immunity against electromagnetic interference, low weight, and loss of signal. I will explain how optical fibers work and how they are made.

How it works?

The transmitter converts the electrical signals into laser or LED light pulses. The light passes through a lens and enters the fiber at an angle that allows having a total reflection inside the fiber’s core. While the receiver converts the light pulses into an electrical signal.

The light must enter the core inside an acceptance cone, otherwise, the light will escape the core.

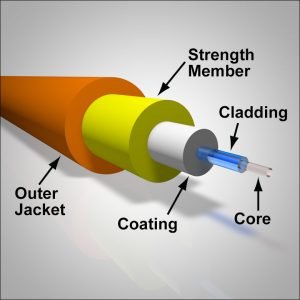

It has three components: the core, the cladding, and the outer coating. The cladding must have a very low refractive index to keep the light in the core. The coating serves as a buffer and the strength member is to prevent the fiber to break.

Optical fiber cables have a central strength member in the middle of the cable.

Types of fibers

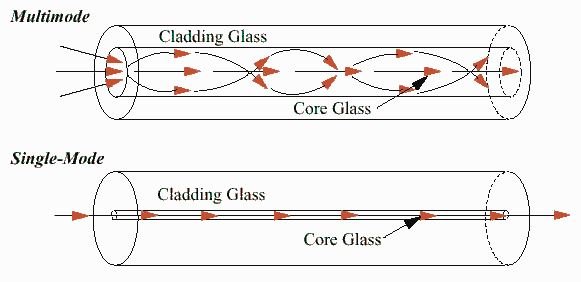

There are two types of optical fibers: single-mode and multi-mode. In single-mode, one single light passes straight through the fiber, and in multimode, the light passes through the core in many modes of propagation.

This figure shows a more detailed comparison between the types.

How it is made?

First, you make the modified chemical vapor deposition (MCVD), consists of rotating a hollow pure glass tube on a lathe. While the tube is rotating, it is heated by a flame moving alongside the tube. Bubbled oxygen through solutions is injected into the tube.

In this process, the chemical reaction happens inside the tube due to the flame’s heat:

SiCl_{4}+GeCl_{4}+2O_{2}\rightarrow SiO_{2}+GeO_{2}+4Cl_{2}

The silicon dioxide (SiO_{2}) and germanium dioxide (GeO_{2}) are formed inside the tube and fused to form the core and the cladding. To keep the glass pure, it must use corrosion-resistant plastics in the valve blocks, pipes, and seals and control the flow and composition of the mixture, this process takes several hours. The result of MCVD is the preform tube showed below.

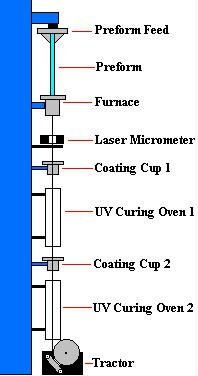

In the next stage, the preform fiber must be sent to a fiber drawing tower as shown below.

The preformed tube goes to a graphite furnace at 1,900ᵒC to 2,200ᵒC, then it forms a thread and goes to a coating cup, and the UV curing oven which function is to quickly dry the coat in the fiber, in some cases pass through a series of coating and UV ovens. Finally, the tractor with controlled speed by the laser micrometer, pull it.